From Day One to Long-Term Success: Onboarding Strategies for Contractors

The construction industry is facing one of its toughest challenges in decades. Companies are struggling to find enough skilled workers while competing to keep the ones they have. At the same time, projects are becoming more complex, deadlines are tighter, and expectations are higher. In this environment, contractors cannot afford to lose good talent.

That is why onboarding matters more than ever. An effective onboarding program does more than welcome a new hire; it sets the tone for their future, builds confidence, and demonstrates that the company values their contribution. Done right, it can mean the difference between an employee who leaves within a few months and one who stays for years.

According to the Bureau of Labor Statistics (BLS) Job Openings and Labor Turnover Survey (JOLTS), the construction industry continues to rank among the highest in employee turnover. Each worker who leaves costs a company an average of $11,500, not counting the disruption to projects and team morale. Only 53 percent of construction workers stay with the same employer beyond two years, and nearly 40 percent of new hires leave within their first 90 days. At the start of 2025, there were still 236,000 open positions across the industry, showing just how competitive the market has become.

Despite these challenges, we must treat every new hire as a potential long-term team member. Remember, you’re building a lasting relationship where their success directly contributes to yours. That’s when onboarding becomes a powerful tool. It is not just about paperwork or orientation, but about making new hires feel connected, valued, and equipped to succeed. Preparation even starts before the employee’s first day.

The Pre-Onboarding Foundation

The success of a hire begins before their first day. Two elements make a big difference.

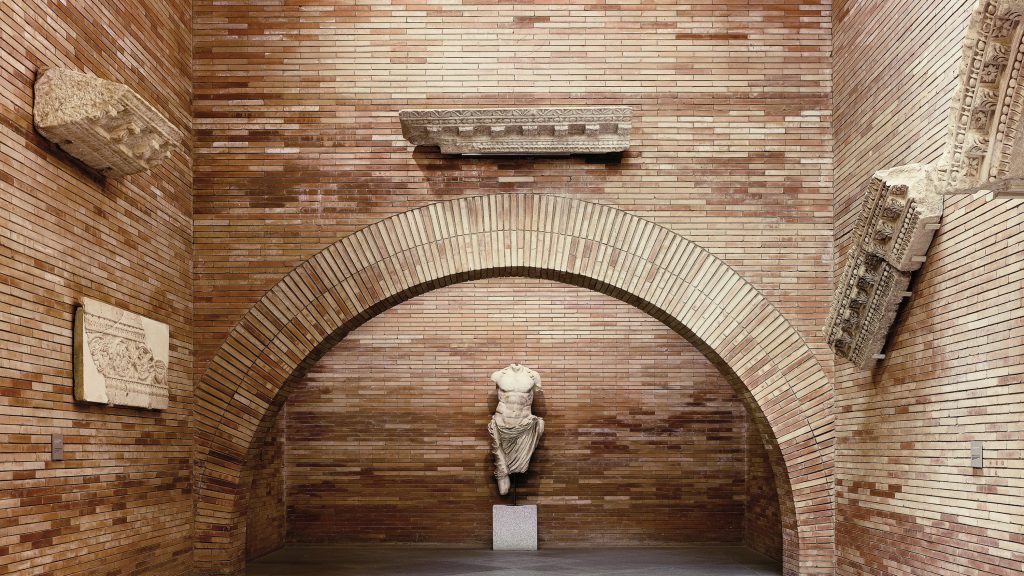

First, validate skills through comprehensive paid skills assessments to maximize the likelihood that you’ve hired the right candidate rather than relying solely on interviews or resumes. For field roles requiring specialized trades, hands-on tests are crucial. For example, having masonry foremen build a brick or block wall (these are masonry materials) in your yard is an excellent way to validate skills and demonstrate expertise. These tests reveal technical ability, attention to detail, and workmanship.

Every trade should have practical evaluations tailored to its standards.

Office roles should test job-specific tasks, such as accountants completing QuickBooks assessments. Hybrid positions like sales executives can be evaluated through project scenarios that require workflow breakdowns, labor hour estimates, and materials lists. Assessments must be challenging enough to reflect real job demands. Using examples from difficult past projects provides the best benchmark.

But pre-onboarding is not only about testing. It is also about discovery. By identifying each person’s strengths from day one, companies gain insights into where new hires can contribute most effectively. Someone may excel in technical execution, while another might shine in organization or communication. Knowing this early helps leaders assign the right responsibilities, foster stronger collaboration, and build healthier work relationships. In short, pre-onboarding is both a tool for preparation and a foundation for team synergy.

But onboarding cannot stop at assessment. Once you know what someone can do, the next step is to give them a clear structure for how they will grow in the role.

Clear KPIs and Mentorship System

A comprehensive 30, 60, 90-day roadmap is essential before onboarding begins. This plan should outline expectations, responsibilities, and milestones for the first three months. Having it ready demonstrates professionalism and respect for the new hire, while also providing a clear path to success from day one.

High-performing employees need clear standards. Defining KPIs allows new hires to track their progress and understand exactly what success looks like. Transparency in metrics reduces uncertainty and builds motivation.

For example, a masonry apprentice might have KPIs tied to learning and applying three core techniques within the first 30 days, such as mixing mortar, tooling joints, acid washing, and proper brick cleaning and alignment. A project manager, on the other hand, might be measured by submitting accurate weekly progress reports and project schedules on time, coordinating at least two successful subcontractor meetings within their first month. An estimator could have a KPI focused on producing three bid proposals each week for a total three-dimensional track against their 90-day period.

Pairing each new hire with a mentor also makes integration smoother. Ideally, the mentor should be at the same level but not the direct supervisor. This encourages open communication without fear of judgment. In construction, where hands-on experience matters most, mentors can pass down practical knowledge that is rarely documented but essential for success.

Once expectations are set and a support system is in place, the next step is to focus on the employee’s early experience, especially during the first week.

Check In Early, Check In Often

The first week sets the tone for the entire relationship. Begin with a “communication check” to confirm all channels and logins work properly and that the employee has every necessary tool. Make expectations about communication frequency clear, and schedule weekly manager meetings to review goals. Remember, “communicate early, communicate often” should guide the process. Regular check-ins prevent small issues from becoming major problems.

The week should follow a structured plan. Start with HR formalities like document review and handbook orientation, then move to introductions, team announcements, or a welcome lunch.

Beyond logistics, the first week is also about making employees feel genuinely valued. Surveys show that the top reasons employees leave include insufficient pay (38 percent), lack of development opportunities (27 percent), poor working conditions (25 percent), and ineffective onboarding (21 percent). Addressing these issues starts early, and even small actions can make a difference.

One effective practice is offering a small but thoughtful welcome gift on the first day. You should know the new hire well enough through the hiring process to personalize the gesture, which makes it feel more authentic. This simple act reinforces that the company sees them as more than just a worker; it shows appreciation and builds early loyalty.

Authenticity is key. A gift should never feel like a gimmick but rather a true reflection of company culture. Yes, even in today’s economy, small investments in people matter.

After the first week, onboarding should not stop. The program needs to continue in a structured way that builds confidence step by step.

Prepare Strategically: A Ship Without Direction Drifts Aimlessly

Breaking onboarding into weekly phases allows employees to gradually absorb information without overload. In construction, this is especially important for learning safety protocols and quality standards.

With 80 to 90 percent of construction companies reporting hiring difficulties, adopting this structured framework can give employers an edge. Preparation, phased training, mentorship, and consistent check-ins are not just theory; they are proven strategies. I have seen companies turn retention problems around by applying these methods and building long-term, reliable teams one successful hire at a time.

But onboarding is about more than just keeping people. It is about raising the bar for the entire construction industry. When companies invest in people, treat them with respect, and provide the tools to succeed, the impact goes beyond retention. It creates safer job sites, stronger project outcomes, and a culture that attracts the next generation of builders. Every contractor who commits to thoughtful onboarding is not only strengthening their own business but also helping to elevate the industry as a whole.

References

Bureau of Labor Statistics. (2025, July). Job Openings and Labor Turnover Survey (JOLTS). https://www.bls.gov/jlt/

original article written by Matt DiBara with photos provided by DiBara Masonry and courtesy of MASONRY Magazine and curated by the MCAA