How To Use Instone’s Game-Changing Virtual Home Design Tool

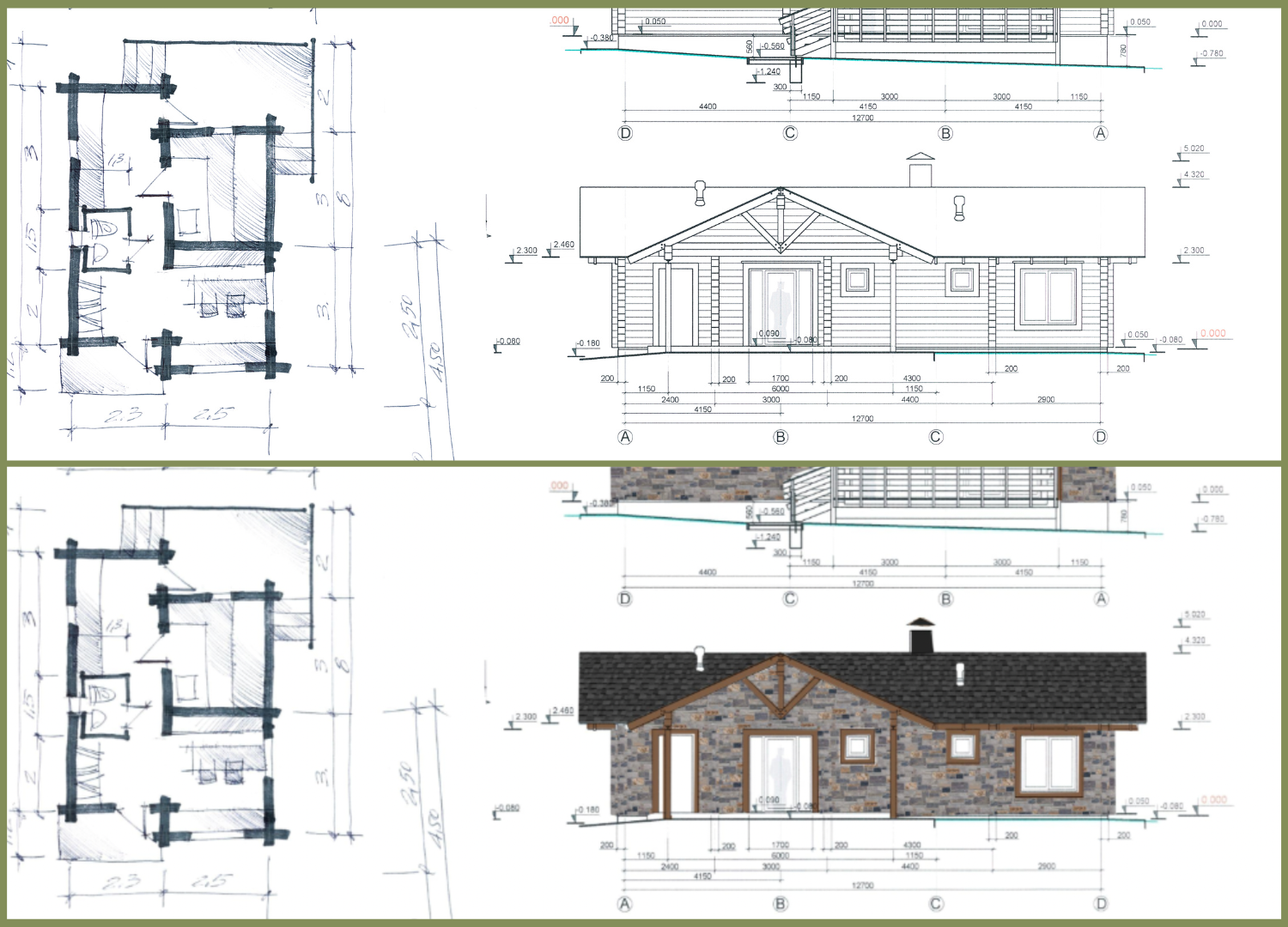

TAKE THIS …

Choose the perfect stone…

GET THIS

With the Instone Visualizer, you can complete a wall-to-wall virtual home makeover in a matter of minutes. The free online tool allows you to simulate what a home or property would look like after a renovation with any combination of stone products from Instone’s expansive catalog.

Powerful yet simple, the Visualizer offers installers and dealers a way to show clients renderings of projects that can be used to assist with sales, and homeowners a way to browse their options for veneers, pavers and other stone products. Users can upload photos of a job site and redo a wall or patio area with new masonry in a couple of clicks.

Instone Vice President of Natural Stone Products Justin Alicandro said the Visualizer has made the need to assemble stone samples or create mockups for clients obsolete.

“This is so much more efficient than the way we used to do things,” Alicandro said. “Homeowners can come out of a session knowing pretty much what they want, and if they don’t like the products once they see real samples, they can tweak the project again in the Visualizer and try a plan B. The Visualizer is such a great tool.”

How It Works

To get started, find or snap a digital photo of your project area and add it to the Visualizer. (If you don’t have an image available, you can browse our samples for one that resembles your property.) Photos should be at least 1600 pixels wide and not exceed 16 MB. A standard camera phone pic will do nicely.

With the photo now online, the Visualizer’s AI will scan its features and automatically identify areas most likely for stonework. The technology will also recognize features like windows and doors and omit them. If it misses a wall or ground section you’re interested in, don’t worry – you can draw a polygon to highlight the area manually.

You can then click on any of these areas and choose the interior or exterior Instone masonry product you’d like to see applied there. Once it appears, you can try different brands, profiles, and colors to see how they look, and even change the stone sizes on the fly. The images you create can be saved, shared, and easily edited later.

Fine-Tuning

The Visualizer has multiple editing tools to help fine-tune your renderings and make them more realistic. You can adjust the opacity of the masonry to totally block out the surface beneath it or to allow important features to peak through. Another tool allows you to adjust the perspective, which can realign the stone if it’s not quite level or doesn’t track the angle of the surface accurately.

For the best results, we recommend taking your photos facing straight ahead toward the surfaces that will be clad. If possible, it’s best to move any furniture or other obstructions out of the way.

The Visualizer will even help you simulate the appearance of non-stone upgrades. You can apply paint colors to your banisters and doors or try out new shingle styles and colors on the roof. These features can be combined with the stone improvements to give you a full picture of how all of the materials will look together.

Share & Create a Report

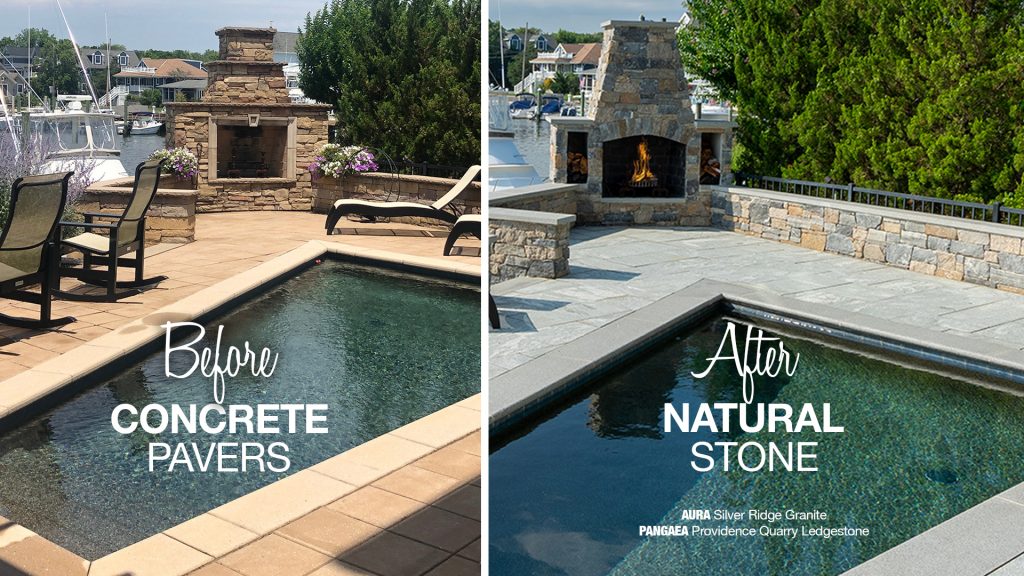

The Visualizer offers a range of options for sharing before and after images with clients or anyone else who may be interested in giving feedback. You can quickly export the renderings as JPG and PNG files or use share buttons to email them or post them to Facebook, Twitter/X or Pinterest.

Of high value to masonry professionals, the system can generate attractively formatted reports showing the finished home and thumbnails identifying all of the products featured in the project.

“For a contractor trying to win a job, price is obviously important, but if you can demonstrate for a homeowner what their house is going to look like when it’s complete, that will definitely set you apart from others trying to quote the job,” Instone Chief Operating Officer Rob McKay said. “Ultimately, a lot of people will still want to see a sample and feel it in their hands, but the Visualizer is a great tool to help them narrow down their choices.”

Watch Our Full Tutorial

For a full demonstration of what’s possible with the Visualizer, watch our training video (“Pro Tips for Selling With The Instone Visualizer”) above. You can also check our Visualizer page for FAQs and a series of shorter videos with tips and demos focused on specific Visualizer questions.