5 Steps to Expertly Source Natural Stone: The Landscape Architects Resource

Published:

Last Updated:

Author:

With more people spending time outdoors, backyard designs are in high demand. And so is beautiful stonework to create all the amenities for luxurious outdoor living: patios, pools, spas, outdoor kitchens, fireplaces and fire pits, as well as the hardscaping: steps, walls and walkways.

5 Steps to Expertly Source Natural Stone: The Landscape Architects Resource

Instone can provide landscape designers and architects with the stone information, samples, technical specs, shop drawings and custom stone fabrication they need to complete projects and satisfy clients.

It starts with a plan set. When that is sent to Instone, the Fabrication and Design Teams get to work to provide the support that landscape architects’ needs.

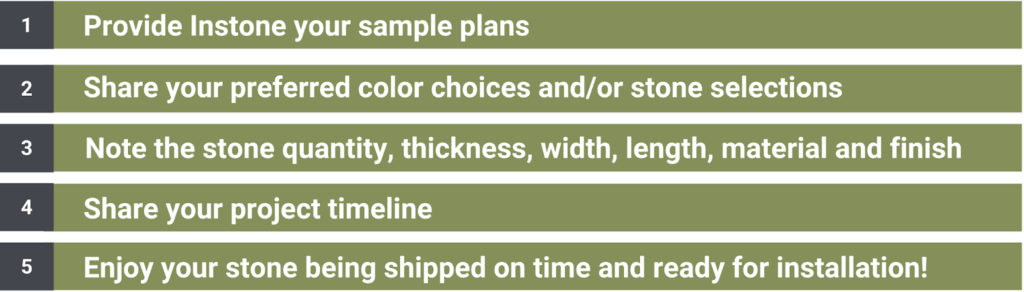

A Stone Sourcing Checklist for Landscape Professionals:

“Availability is key,” says Instone’s senior estimator, Nicole Blackburn. “We can let them know what standards we have in stock and how fast they can get it. We provide samples for their requests. We’ll also provide options based on our experience and expertise. We will let them know the time it will take to get the product and the price point so they can take it back to the homeowner to decide on what they want.”

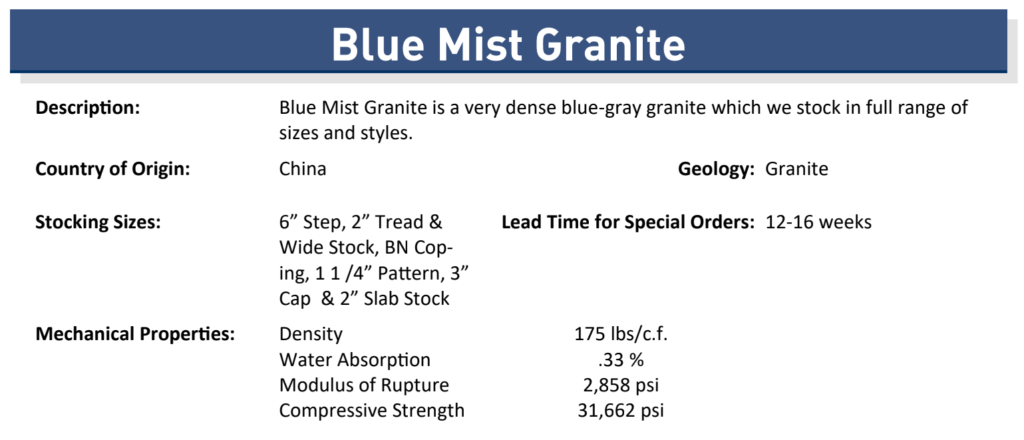

Instone also gives landscape architects the technical data including the stone’s stocking sizes and country of origin, as well as mechanical properties such as density, water absorption, and rupture compression strength.

Example of the product specification Instone provides for each of its Aura stone products.

“Usually, they want to know the density of the stone, how durable it is, how it will hold up under the weather conditions and if the stones get hot underfoot. We can provide all of that information,” says Blackburn.

When the Fabrication and Design Teams receive a plan (or drawing) set of a full backyard design, takeoff and stone schedule, they then provide an estimate to a local stone distributor. Once the quote is approved, the shop drawing process begins for each stone. It includes the type of stone, dimensions, finish and fabrication work such as edging and placement according to the stone schedule. Instone works closely with local distributors, landscape designers and contractors to ensure the shop drawing is perfectly constructed and accommodates their needs.

Once all parties approve the specifics, the work begins with fabrication cuts on the natural stones to prepare them for installation.

Because timing is everything with stone, Blackburn advises homeowners and landscape architects to plan ahead. “Most people want to start backyard projects as soon as winter is ending. The weather is warming up, and they want the stone quickly. They may be limited to what we have in stock, or they will have to wait if their heart is set on a particular stone, we work to get it for them.” She recommends people start their planning process before or during the winter months, so if there is some wait time, the project will be completed by the start of summer.

Instone’s Fabrication and Design Teams are here to help landscape architects and designers get what they need quickly and professionally to create beautiful outdoor living spaces for their clients.