Introducing Game-Changing Stone Veneer Enhancements

Tradition Meets Innovation:

Undeniable Impacts & Benefits for Instone Customers

A trio of innovations pioneered by Instone stone veneer producers are bringing a new level of convenience, durability, and sustainability to the industry. With reimagined packaging solutions, a patented water management system, and a modular wall system, these Instone products are creating exceptional experiences for masonry professionals and their clients.

Scroll below for a tour of these remarkable features and their benefits.

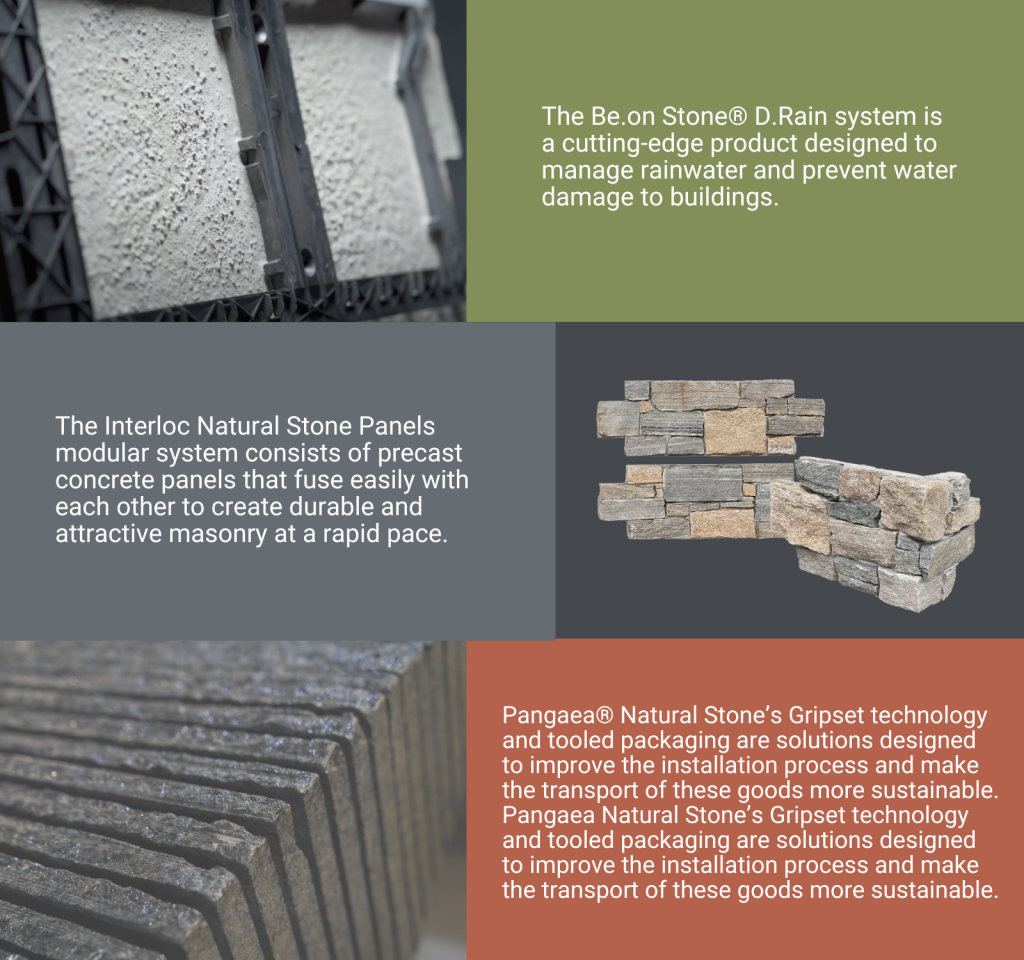

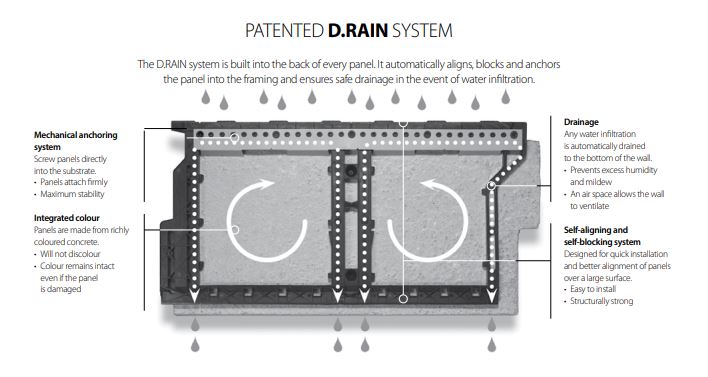

Stone Siding Gutters Stop Water Damage

Be.on D.Rain

With Be.on Stone exterior veneers, any water that sneaks through the joints goes down the D.Rain. The patented and inventive D.Rain system collects and channels rainwater down through a gutter-like system affixed to the back of each stone panel, releasing it into the ground at the bottom of the building. The system was specially designed to protect building exteriors from damage that can be suffered over time from continued moisture exposure.

Vince Frassinone, president and owner of Seal Tight Exteriors, based in Steger, Illinois, recently tried Be.on Stone for two home builds. It was recommended to him by a local supplier who praised it for both its innovation and simplicity.

“A lot of other stone products absorb water, and when they do, it gets behind them and starts rotting the structure,” Frassinone said. “With Be.on Stone, everything is being captured with a rain-screening system, so if something does get behind it, it gets out fast and dries up.”

Streamlined Installation

Be.on Stone, a mechanically fastened veneer panel, also known as “screw-on stone veneer” or “stone veneer siding,” is also known for its ease of installation. The installation process is estimated to move as much as four times faster than a conventional veneer project thanks to Be.on Stone’s mortarless stone panels, which can be screwed directly into the studs or substrate. All an installer basically needs is a screw gun, a saw, a grinder, and a level.

Frassinone said there was a brief learning curve when his team started its first installation project, but once they got the hang of it, the rest of the project and his second one went quick and easy. Over a year after both installs, he said both homes look brand new and the Be.on Stone has done its job to perfection.

Be.on Stone comes in a variety of colors, distinctive styles, and finishes that can transform a home or building’s exterior to create curb appeal. Customers can use the Be.on Stone Visualizer to create an instant virtual rendering of what their home would look like with its various colors and patterns.

Check out our Inbuilding Design Video Featuring Be.On stone below!

Eliminate Slippage During Stone Veneer Installation

Pangaea Gripset®

Through its patented Gripset technology, Pangaea pre-scores grooves onto the back of each stone during manufacturing. When applying the stone, the grooves allow stones to quickly and effectively grip onto mortar, expediting the installation process and ensuring the work will hold up well for many years.

Prefit Leads to Less Waste

Pangaea’s thin stone veneer is pre-cut, tooled, trimmed, and fitted, providing a mason with simpler installation and increased quality control. Each pallet layer is pre-blended for optimal color variance and size ratio, saving time and money before installation.

In addition, the company’s packing crates are specially designed to thwart the spread of invasive pest species. The pine used is inspected to ensure that its moisture levels are too low to harbor insects and each crate is International Plant Convention (IPC) certified and stamped.

Check out our Inbuilding Design video featuring Pangaea Natural Stone below!

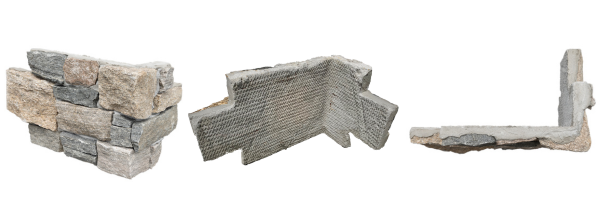

Install Natural Stone 8x Faster With Predesigned Interloc Panels

As the name implies, Interloc natural stone veneer panels are engineered to interlock seamlessly. Each panel contains several pieces of stone, allowing installers to cover a surface up to eight times faster than it would take for a typical stone-by-stone job.

The corner pieces of the Interloc Panel System provide a smooth transition between wall sections. These shapes of the corner pieces match the profile of the Interloc panels, and are available in a variety of sizes to accommodate different wall heights and thicknesses.

Made from the same high-quality concrete as the Interloc panels themselves, the corner pieces ensure that they provide the same strength and durability as the rest of the wall. They interlock with the adjacent panels, providing a tight and secure fit that prevents shifting or movement over time.

Learn More: Find out what these innovations can contribute to your home and commercial property projects. Contact Instone today at customerservice@instoneco.com or (708) 371-0660 to consult one of our experts on Be.on Stone, Pangaea Natural Stone and Interloc Natural Stone Panels products.

What a great blog article!